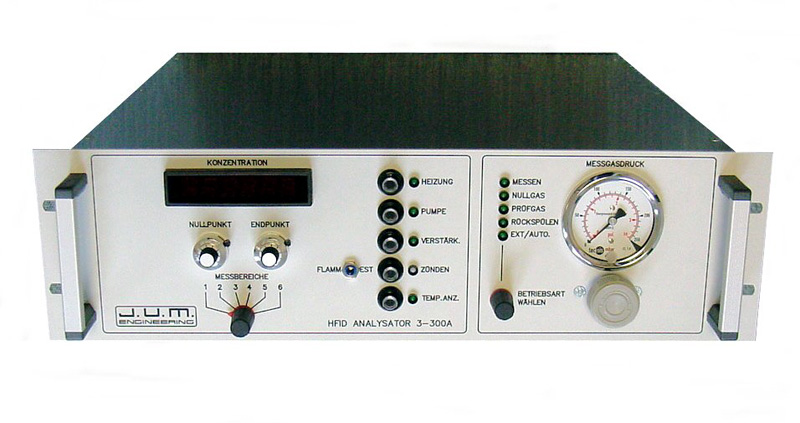

FID Analyzers

Most heated FID analyzers described in here are TÜV confirmed to fully comply with QAL 1 (EN 14 181 and EN ISO 14956) and EN12619 regulations. They also fully complies with USEPA Method 25A and Method 503.

All use an identical analytical circuit to warrant identical measurement results. They are equipped with our permanently installed, internal 2 micron stainless back purge sample filter. Compressed and dry air or nitrogen is applied for cleaning and regeneration. Cleaning typically takes just a few seconds and maintains every attached sample line; Our back purge feature not only cleans the internal sample filter. When a sample line is attached between the sampling probe and the analyzer, this line (with probe) is automatically cleaned with every filter cleaning process. No sample probe filter is needed when the FID is used as a stand-alone unit. Back purge typically takes less than 30 seconds which means nearly uninterrupted operation of the FID analyzer during filter cleaning is the result.

The sample filter back purge feature can be replaced with our quick change disposable 2 micron sample filter in the heated oven in stead of back purge sample filter. It is easily accessible in rear panel without special tools. This OVE Option reduces the analyzer price by approx. 20%.